Page 16 - HancockClassics2019_forweb

P. 16

WHEN THE SOLUTION BECOMES THE PROBLEM

®

BACKGROUND - Since its introduction in 1992, Energy Star certification has been the 'Holy Grail' for

manufacturers of electronics, lighting, appliances, and

building materials, especially windows. The certification

is the consumer’s assurance that the product bearing the

®

Energy Star label is among the most energy efficient

in its class. And because the designation is given only to

the top performers within their class, achieving Energy

Star certification has prompted window designers and

®

manufacturers to continually produce better and more

energy-efficient products. The Holy Grail of Performance

Four climate zones define the country

®

When first adopted, Energy Star certification was fairly easy to achieve. Usually, a thermally improved frame with an Insulating Glass Unit

would qualify. However, over the subsequent decades, the Environmental Protection Agency has required gradually improved performance

in order to qualify.

THE QUANDARY - Keeping pace with these demands for improved performance

has taken the combined efforts of the entire industry, including manufacturers and their

suppliers of framing, glass, sealants, hardware and other components. Ultimately, every

incremental performance improvement comes with an exponentially higher price tag.

Under Energy Star 6.0, the stringent U-Factor required in the Northern zone

®

(U=0.27 or better) has proven to be an extremely difficult performance level for

many manufacturers to achieve. As frequently happens, government regulations and

mandates require solutions that are beyond the performance limits of a product’s

design. When this occurs, manufacturers either replace the old product, or they Every incremental improvement costs exponentially more

explore alternate methods of meeting performance criteria, some of which may have

unintended consequences.

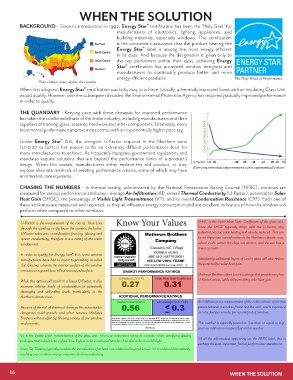

CHASING THE NUMBERS - In thermal testing, administered by the National Fenestration Rating Council (NFRC), windows are

measured for various performance attributes – average Air Infiltration (AI), overall Thermal Conductivity (U-Factor), potential for Solar

Heat Gain (SHGC), the percentage of Visible Light Transmittance (VT), and its overall Condensation Resistance (CRF). Each one of

these attributes are measured and reported, as they all influence energy consumption and are excellent indicators of how the window will

perform when compared to other windows.

Know Your Values SHGC is the Solar Heat Gain Coefficient of the glass unit.

U-Factor is the measurement of the rate of Heat Loss

through the window, so the lower the number, the better. Since the SHGC typically drops with the U-Factor, any

U-Factor takes into consideration framing, glazing and potential passive solar heating will also be reduced. This can

spacer conductivity, therefore it is a rating of the entire be an important consideration in the Northern climate zone,

where in the winter the days are shorter, and the sun has a

window unit.

lower azimuth.

®

In order to qualify for Energy Star 6.0, some window

manufacturers have had to resort to providing so-called Introducing additional layers of Low-e glass will also reduce

'S4' Glazing, wherein the interior surface of the window the potential for solar heat gain.

contains an exposed Low-e (low emmissive) surface.

Mathews Brothers offers Low-e coatings that provide very low

While this option will result in a lower U-Factor, it also U-Factor values, while still permitting solar heat gain.

increases interior levels of condensation to potentially

damaging and unhealthy levels, particularly in the

Northern climate zone.

Air Infiltration is a measurement of the cubic volume of air that

Because of the risk of sheetrock damage, the potential for passes between a window frame and the sash, and is expressed

dangerous mold growth, and other reasons, Mathews as cubic feet per minute, per square foot of window.

Brothers will not offer S4 Glazing on any of our window

or door units. This number is typically posted as ‘less than or equal to 0.3’,

since air infiltration is a pass/fail at that number.

VT is the Visible Light Transmittance of the glass unit. This is an important rating to consider when specifying glazing

packages that include Low-e glass. Low-E glass reduces radiated heat loss, but also reduces visible light. Of all the information appearing on the NFRC label, this is

perhaps the least important, from a performance standpoint.

Since 'S4' Glazing typically involves the introduction of at least one additional layer of Low-e, VT is reduced dramatically,

resulting in a condition many consumers find unsatisfactory.

16 WHEN THE SOLUTION